Labour Shortages Drive Mechanisation in Agriculture: The Sugarcane Harvesting Revolution in Maharashtra

(Source: Indian Express; Section: Explained; Page: 16)

| Topic: GS3 – Agriculture |

| Context: |

|

Analysis of News:

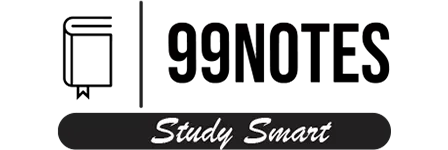

About Farm Mechanisation in India

- Farm mechanisation refers to the adoption of machinery and technology in various agricultural operations. It plays a pivotal role in enhancing productivity, reducing manual labour, and ensuring timely and efficient farm practices.

- In India, where agriculture remains a backbone of the economy, mechanisation becomes even more critical.

Labour Shortages in Agriculture

- Labour shortages in agriculture are driven by the physically demanding nature of tasks like transplanting, spraying, and harvesting, coupled with alternative employment opportunities in sectors like construction and manufacturing.

- Government welfare schemes such as MGNREGA and direct cash transfers have further increased the opportunity cost of agricultural work, prompting rural labourers to seek less taxing livelihoods.

Impact on Mechanisation and Herbicide Use

- The decline in manual labour availability has accelerated the adoption of mechanisation in Indian agriculture.

- For example, mechanised solutions, such as sugarcane harvesters, have started replacing traditional manual practices in states like Maharashtra.

- Additionally, the use of herbicides has risen to address labour shortages in manual weeding.

Sugarcane Harvesting in Maharashtra: Traditional System

- In Maharashtra, sugar mills, rather than farmers, manage sugarcane harvesting through muqaddams (middlemen) who organize labour gangs (tolis).

- These gangs, largely composed of migrant workers, are supervised by the muqaddams, who also coordinate with mills to ensure consistent cane supply.

- However, this system faces challenges due to labour shortages, aging workforce, and instances of workers not reporting for duty after receiving advances.

Rise of Mechanical Harvesters

- The deployment of mechanical harvesters, pioneered by mills like the Manjara Farmers’ Cooperative in Latur, is transforming sugarcane harvesting.

- With increased efficiency and reduced dependence on labour, mills like Manjara now aim for 100% mechanisation.

- Mechanical harvesters also enable better cane recovery by cutting the stalk closer to the ground, enhancing sugar extraction efficiency.

Economic Viability of Mechanisation

- Farmers in Maharashtra have invested significantly in mechanisation, supported by cooperative bank loans.

- While the initial investment is high, the operating costs—including labour, maintenance, and diesel—are offset by the efficiency and profitability of mechanical harvesting.

- Entrepreneurs in this space report substantial returns, showcasing the financial feasibility of this shift.

Challenges of Mechanical Harvesting

- Despite its advantages, mechanical harvesting has drawbacks.

- Machines chop cane tops into fine pieces, making them unsuitable for fodder—a key source of animal feed in states like Uttar Pradesh.

- However, proponents argue that the chopped tops enhance soil health by acting as organic mulch, improving water retention and nutrient cycling.

Future Prospects

- The mechanisation of sugarcane harvesting is expected to grow, with mills increasingly adopting advanced technologies.

- Scaling up mechanisation across multiple mills, coupled with innovations to address fodder challenges, can further enhance agricultural productivity and sustainability in India.

| Global Comparisons |

|

| Practice Question: Discuss the impact of labour shortages on agricultural practices in India, with a focus on the increasing adoption of mechanisation in sugarcane harvesting. What are its benefits and challenges? (250 words/15 m) |